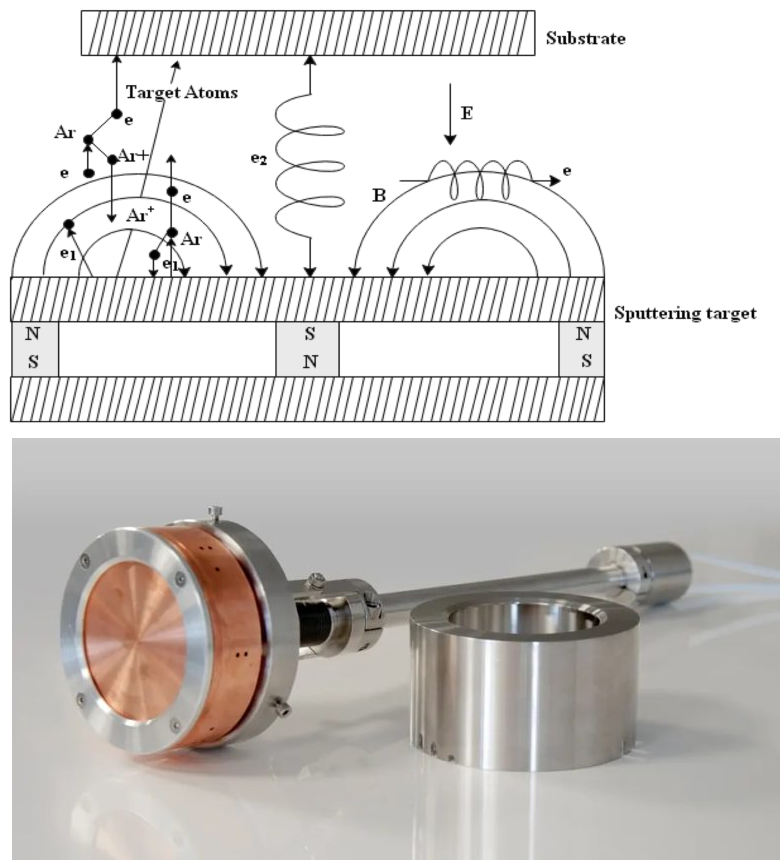

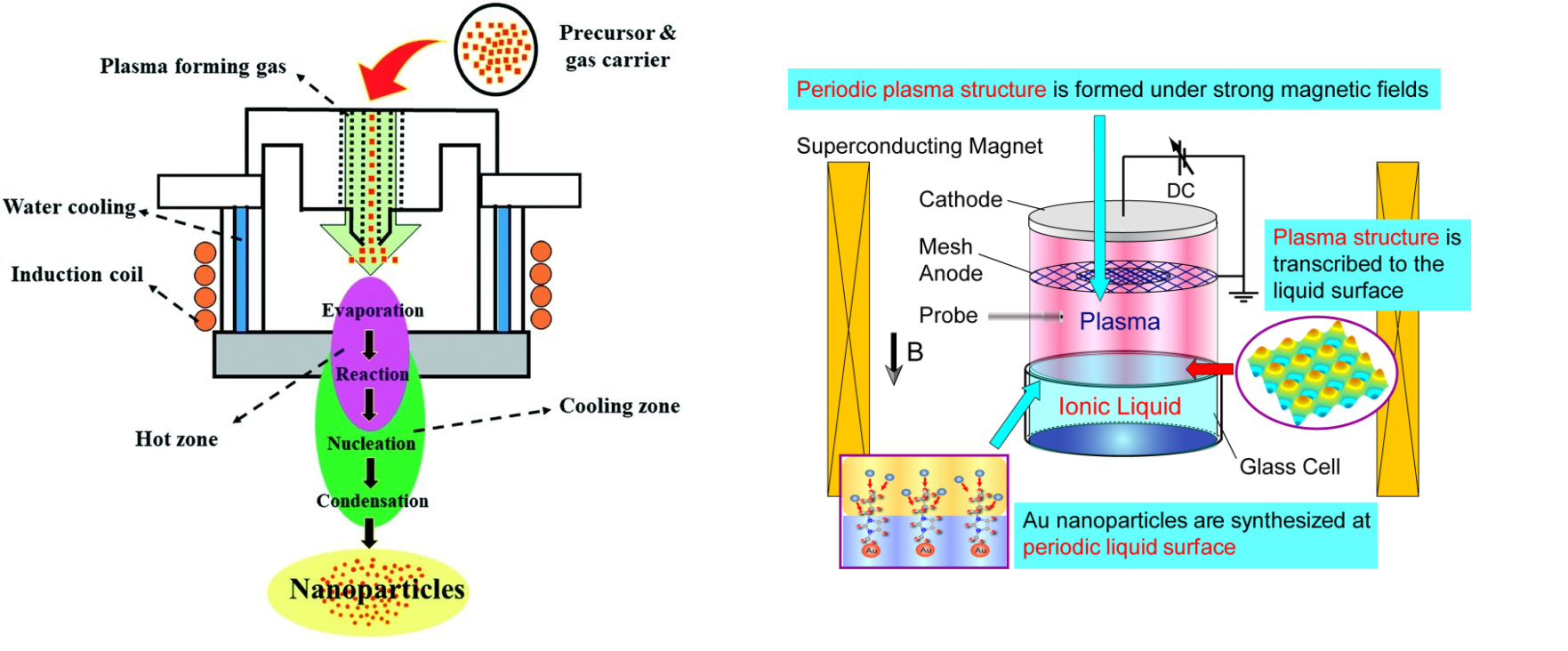

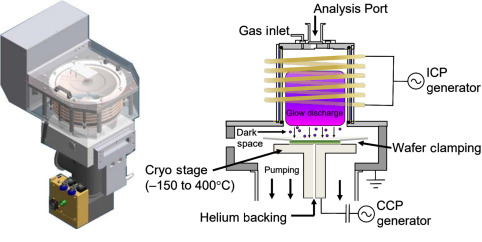

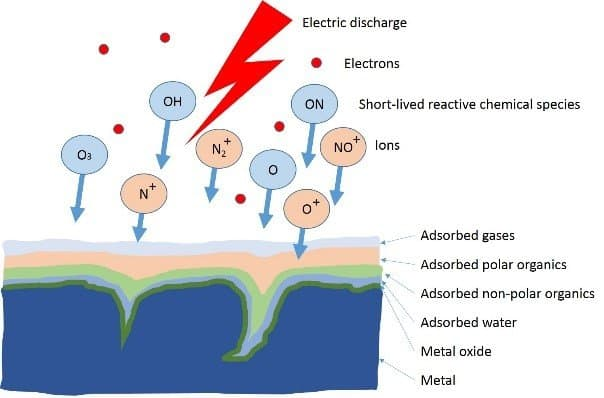

Magnetron sputtering deposition is a fast technique for applying a thin layer of inorganic materials on a substrate. Magnetron sputtering is the collision process between incident particles and targets. Since high-speed sputtering is performed at a low pressure, it is necessary to effectively increase the ionization rate of the gas. The incident particle undergoes a complex scattering process in the target, collides with the target atom, and transmits part of the momentum to the target atom, which in turn collides with other target atoms to form a cascade process.

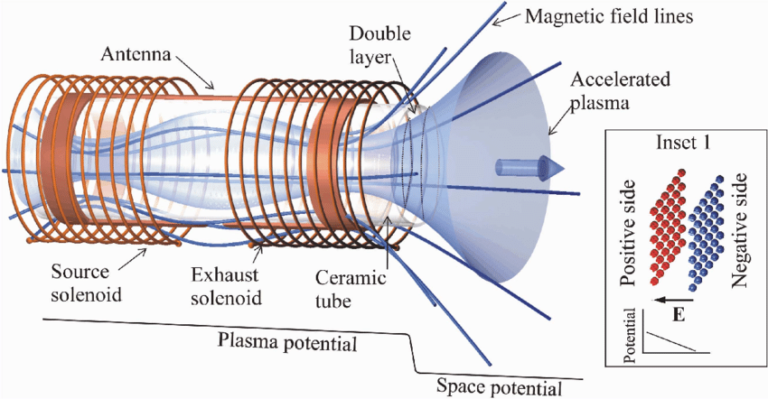

The interaction between the magnetic field and the electric field causes the electrons to spiral in the vicinity of the target surface, thereby increasing the probability that electrons will strike the argon gas to generate ions. The generated ions collide with the target surface under the action of an electric field to sputter the target. The target source is divided into balanced and unbalanced types; the balanced target source is uniformly coated, and the unbalanced target coating layer and the substrate have strong bonding force.

Balanced target sources are mostly used in semiconductor optical films, and unbalanced are mostly used in wear decorative films. Sputtering metals and alloys with a magnetron target is easy, and it is convenient for ignition and sputtering. Magnetron reactive sputtering insulators appear to be easy, but it is difficult for practical operations.

Types of magnetron sputtering:

-

▶ Unbalanced magnetron sputtering

-

▶ Closed-field unbalanced magnetron sputtering

-

▶ Pulsed magnetron sputtering

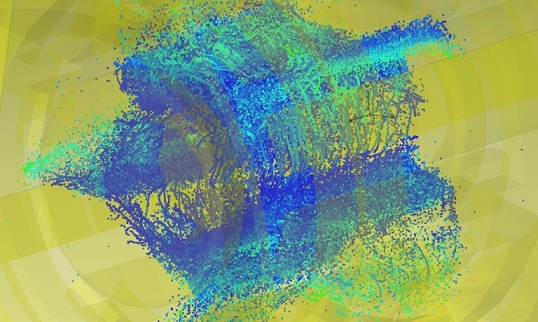

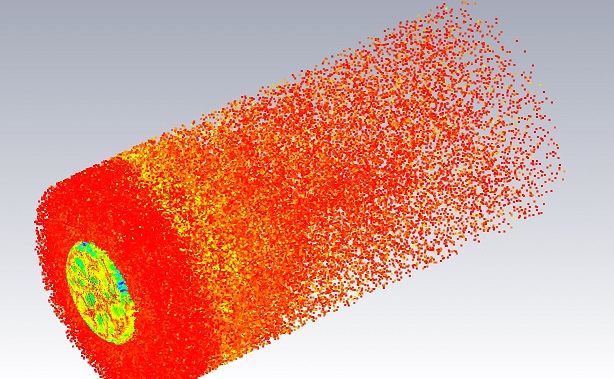

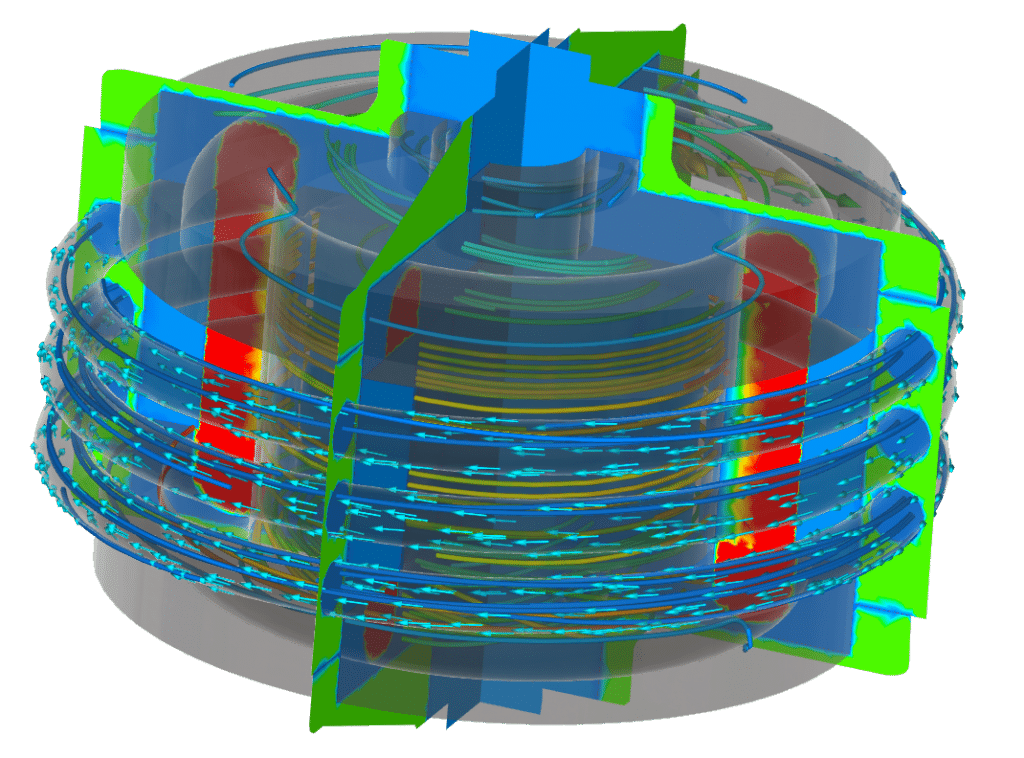

Numerical simulation of sputtering process requires accurate models of nuclear stopping in materials, particle dynamics and self-consistent electromagnetic fields. Based on the problem details, Particle‐in‐Cell/Monte Carlo Collisions technique it includes techniques for the gas heating and the diffusion transport of the sputtered atoms. An external electric circuit is incorporated to achieve the calculation of the cathode voltage in a self‐consistent manner, as well as the simulation of the constant current regime.